|

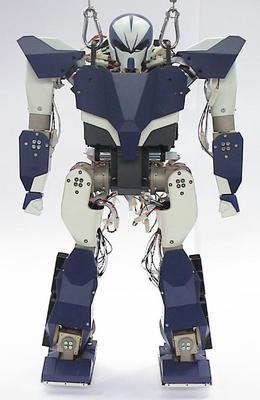

Name: | UT-mu |

| Pop-name: | mighty | |

| Height: | 58[cm] | |

| Weight: | 6.5[kg] | |

| Main structure: | AZ91D(magnesium alloy) | |

| density=1.81[kg/cm^3] | ||

| Num.of joints: | 23 | |

| neck 3(unactuated) | ||

| arm 4x2 | ||

| leg 6x2 | ||

| Power source: | NiH battery or external supplier | |

| Voltage: | 24V | |

| Main CPU: | Geode GX1 | |

| Actuator: | coreless DC motor | |

| Gear: | harmonic drive gear |

UT-mu is our prototype, completed in 2003. It is nicknamed "mighty" with a desire to be a mighty robot. All the joints feature a combination of coreless DC motor manufactured by maxon(4.5W×2:shoulder-rotational, 6.5W×4:shoulder-abductional, elbow, hip-rotational, 11W×12:reminders) and harmonic drive gears by Harmonic Drive Systems(dec.ratio 100:1). The key to save size and weight even with such high-spec motors and gears is its modularized joint design with ortho-axis-coupled gear units and magnesium-alloy-casting exoskeletal structure.

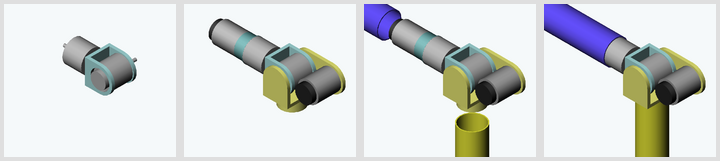

The above illustrates the basic structure of joints. "Humanoid" in terms of structure has one charactor that many pairs of adjacent joint axes are mutually parpendicular. Based on this fact, we designed ortho-axis-coupled gear unit with two harmonic drive gears. Assigning motors to each input axis and connecting those joint modules by thin-shelled(t=0.8-2.0) magnesium-alloy-casting exoskeletons, we can

- make body light but stiff

- accelerate production cycle, sharing common parts

- reduce the number of parts

- improve maintainability with easy assemble-and-disassemble of joints (pic.)

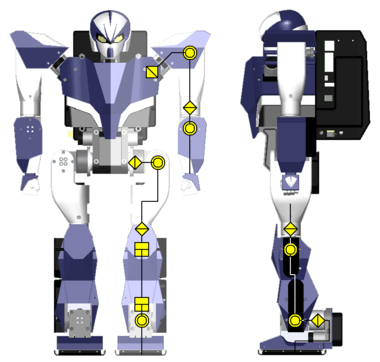

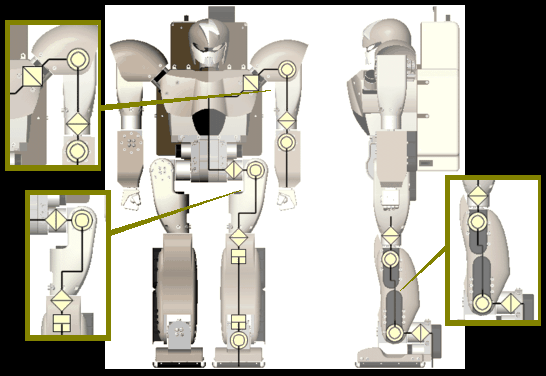

UT-mu is distiguished from other robots by its unique joint assignment shown above.

- I.shoulder

- It is said that one of the most human-like motions appears in the shoulder. The root axis of each shoulder which is slanted from the perpendicular axis to 45 degrees generates a natural flavor on its mixed motion of extension and abduction in a simple way. (pic.)

- II.hip

- Two axes of the hip joints are assigned so as to enlarge the motion range of flexion-extension and abduction. The distance between the two hip joints is countered by inward offset of knee rotation joints to prevent the sideward perturbation of the trunk. (pic.1) (pic.2) (pic.3) (pic.4)

- III.knee - ankle

- The ankle flexional joint is assigned with a small offset backward to the hip and knee in order to exclude singular posture out of the motion range. And, the mechanical stopper at the knee flexional joint saves kinematic energy in the stretched-knee posture.

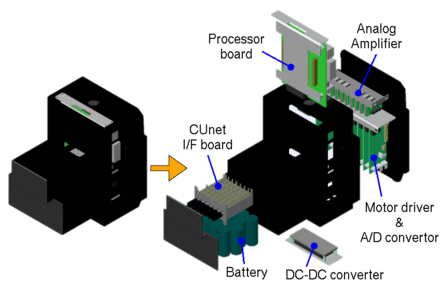

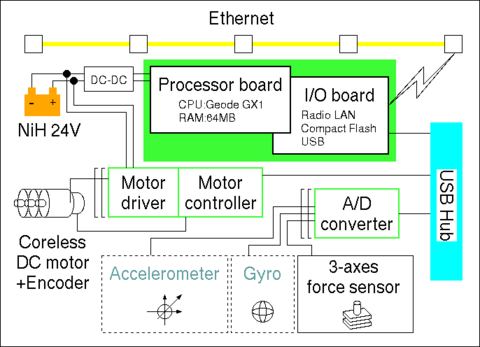

The above shows the hardware system of UT-mu. It is an independent system, having the processor board and battery within, and excluding any cables from outer resources which disturbs robot's motion. The processor board is CARD-PCI/GX(EPSON) which features CPU Geode GX1(National Semiconductor) with a customized I/O board(Fujitsu Automation). Communication with ethernet is ensured via wireless LAN card(melco), so that it can be remotely operated. It also has the internal USB LAN which branches at USB Hubs(Sanwa supply), and communicates with actuator drivers and A/D converters. The DC motors are controlled by the motor controller iMCs01 + amplifier iMDs03(iXs research corp.). The input signal from sensors, which includes the gyro sensor MG2(Microstone), the accelerometer MA3(Microstone) and the 3-axis force sensor PicoForce(NITTA), are processed at A/D converter iMCs03(iXs research corp.).

[Gallery]

- Front view

- Side view

- Size comparizon with PET bottle

- Size comparizon with sake bottle

- With Fighting Spirit

- Glowing eyes in the dark

- Gazing at the space

- Before assembly

- COG displacement in sideway(MPEG、667K)

- COG displacement on diagonal(MPEG、849K)

- Knee-bending(MPEG、1.2M)

- Side step(MPEG、657.K)

- Stamping(MPEG、723K)

- Forward walking 0.7sec/step(MPEG、773K)

- Forward walking 0.5sec/step(MPEG、825K)

- Stepping variation(AVI、67M!)

This project was supported by "Robot Brain Project" under the Core Research for Evolutional Science and Technology (CREST) program of the Japan Science and Technology (JST) Corporation.